|

Shanghai Sealion Machine Tool Co., Ltd

|

Double Column Vertical Lathe

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

2-Axis CNC Double Column Vertical Lathe

We strive to continuously introduce advanced technology to the industry and deliver by working closely with our CNC machine tool manufacturers. We are focused on developments to increase quality and best lathe machine for our customers. Sincerely welcome to visit our company or contact us for cooperation.

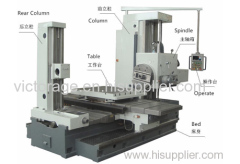

Conventional Double Column Vertical Lathe, Regarding the column heightening model, there is a double sliding column system. The cross beam can move up and down to achieve better cutting accuracy. We have several models to be selected for the best cutting need.

Features of Conventional Double Column Vertical Lathe

The CNC double column milling machine is suitable for rough or fine machining of auto, bearing, wind power, motor, and water pump, etc.

The base and column use one-piece high-quality castings.

Hydrostatic Table.

X&Z is using a brand linear guideway.

The main transmission is driven by frequency or a servo motor, simple structure, and high transmission efficiency.

Servo motor and gearbox directly drive the Ballscrew for X&Z axis feeding. It can reach high accuracy and fast-moving.

Full cover is your optional together with a chip conveyor and coolant system.

Handheld Unit.

Twin spindle twin turret and twin spindle twin turret CNC lathe.

Application Field of Double Column Vertical Lathe

1. Double column vertical lathe is mainly used for processing medium-sized tire molds, flanges, various valves, pipes, pressure vessels, propellers, steam turbine parts, plastic molds, shafts and other workpieces.

2. Suitable for processing inner/outer cylindrical surface, conical surface, end surface, etc.

3. Spindle bearings are selected from domestic well-known brand companies.

4. The spindle box adopts a symmetrical structure to make the thermal deformation uniform and avoid the deviation of the double column machining center.

5. The gears in the headstock and guide rails are all quenched to ensure precise transmission and high rigidity.

6. The twin spindle lathe is inlaid with zinc alloy wear-resistant guide plates, which can be in contact with the pressure oil between the guide rails to improve the load-bearing capacity of the worktable.